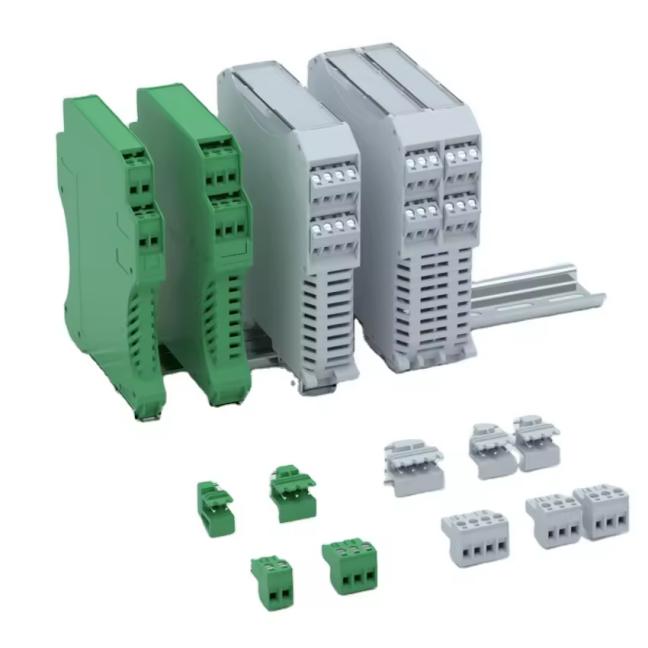

Din Rail Enclosure—The Best Solution for Protecting Electronic Instruments

2024-12-23Electronic instruments may encounter collisions or vibrations during use, especially in industrial environments. External impacts can damage internal circuits or components, leading to equipment failure. These instruments often contain precise circuits and components that are highly sensitive to dust, moisture, and humidity. Electromagnetic interference (EMI) from external sources, particularly in industrial or medical settings, can cause equipment malfunctions. These multiple factors necessitate protective housing. In industrial automation, rail housings are commonly used. The standard rail design is both universal and space-saving. Electronic instrument enclosures not only ensure stable operation but also extend their service life, enhance safety, and improve the user experience.

We will now provide a detailed explanation of the functions of din rail enclosures from the following aspects.

Physical Protection:Din Rail enclosures provide a sturdy protective enclosure for electronic instruments, preventing damage from external physical impacts, vibrations, or falls during operation. This enhances the durability and lifespan of the equipment.

Dust and Water Resistance:Din Rail enclosures are typically designed with dust and water resistance, effectively preventing contaminants such as dust and moisture from entering the internal components of the equipment. This is especially important in industrial environments, as it protects the instruments from harsh conditions and ensures their stable operation.

Electromagnetic Interference (EMI) Protection:Din Rail enclosures often feature effective electromagnetic shielding, which can significantly reduce or block external electromagnetic interference. At the same time, they help minimize the electromagnetic radiation generated by the equipment, reducing its impact on the surrounding environment.

Heat Dissipation:The structural design of Din Rail enclosures typically takes heat dissipation into account, helping electronic instruments effectively dissipate heat during prolonged operation and preventing overheating that could lead to equipment failure.

Neat and Organized:Din Rail enclosures allow multiple electronic instruments to be neatly arranged on the same rail, making the entire control system appear more organized and easier to manage and inspect.

Space-saving:Din Rail enclosures have a compact design, saving space required for the equipment, which makes installation in limited spaces, such as control cabinets, more efficient.

In summary, Din Rail enclosures not only effectively protect electronic instruments from external environmental influences but also offer multiple advantages in terms of installation, heat dissipation, and shielding. They are an ideal solution for safeguarding electronic equipment.